|

Specifications

|

|

Effective strokes 1

|

|

X axis

|

2800 mm

|

|

Y axis

|

2200 mm

|

|

Z axis

|

850 mm

|

|

A axis

|

+/- 370o

|

|

C axis

|

+/- 370o

|

|

V axis

|

2200 mm

|

|

Effective strokes 2

|

|

X axis

|

3100 mm

|

|

Y axis

|

650 mm

|

|

Z axis

|

850 mm

|

|

A axis

|

+/- 370o

|

|

C axis

|

+/- 370o

|

|

V axis

|

650 mm

|

|

CNC system

|

Taiwan New Generation 200-5

|

|

Spindle

|

Italy, 9.6 Kw (Manual tool change)

|

|

Vacuums

|

4.5 Kw

|

|

Speed

|

160 cubic meter / hour

|

|

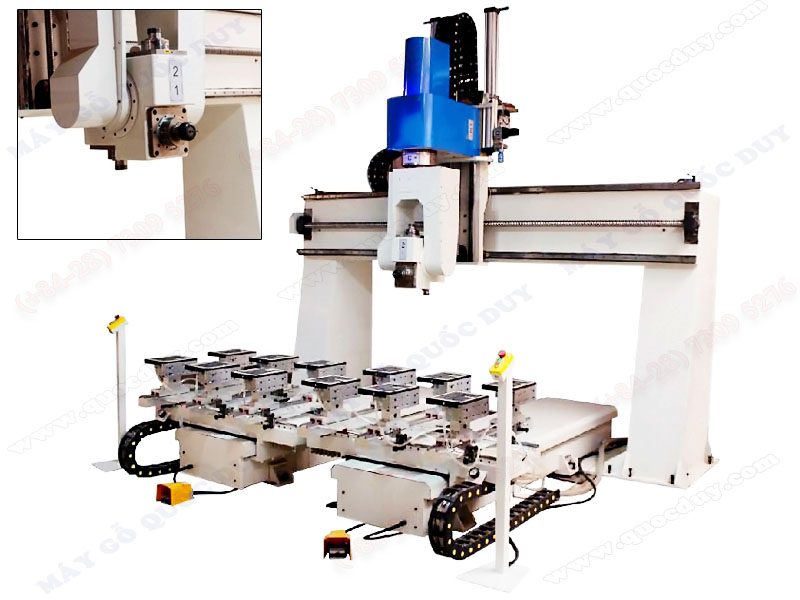

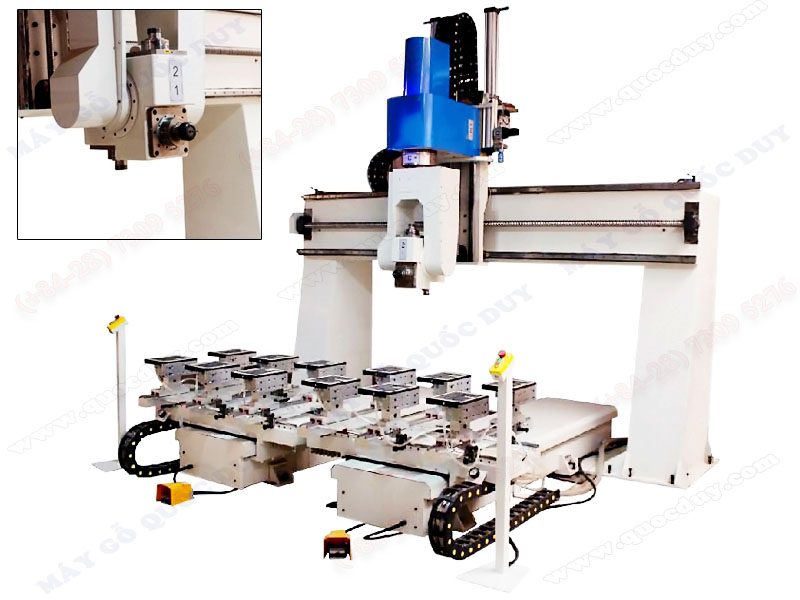

Dimension

|

6750 x 2900 x 3360 mm

|

|

Weight

|

6000 kg

|

CNC system: Taiwan New Generation 200-5

Control high-precision HPCC orbit

High-precision trajectory control using appropriate curves to match straight knife paths into continuous orbit without being confined by intermittent sections in the processing scheduling and by that can get excellent processing quality.

|

|

|

SPA2.0 (ZPEC) - Return journey by servo motor

Optimization of compensation algorithms to further enhance the arc and angle accuracy, improve path symmetry, enhance anti-vibration.

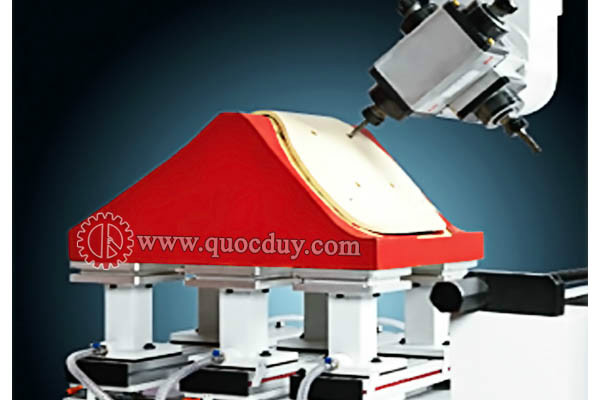

RTCP engine head control function

Provides three-dimensional tool length compensation function, users only need to calculate the contour coordinates of the workpiece shape on the CAM software, the controller will automatically take into account the knife length and wear value, the work point Always in!

|

|

Servo controller

|

|

|

VACUUM PUMPS

Vacuum pump rotary fan, air cooling by double fan, oil / air heat exchanger. Equipped in standard with fine mesh filter, non-pressure backpressure valve, dynamic ball valve, protection shell and oil separator. Protection class IP54, insulation class F.

|

|

Configures drill head with two separate spindle motors (four main spindles). The minimum distance between the axes allows for movement between different jobs thus allowing for faster working time

|

|

|

|

The machine is equipped with two desks that allow the operator to load an area while the machine is working on other embryos.

Each area is provided with 3 rail rails along X, each area is equipped with 2 suction tables - 6 support bars for each area.

|

Linear Guide: Taiwan

Structure:

-

The slider is lubricated

-

Stainless Steel

Prevent dust from entering the slider from the bolt hole

|

|

|

|

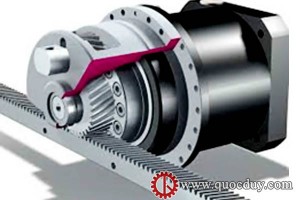

X and Y axis

The X-axis and the Y-table are made through the toothed rack and bracket. They slide on linear rails with pre-loaded roller bearings, brush motors and digital actuators

|

Screw:

Screw TBI MOTION high reliability based on product technology accumulated over the years, materials, heat treatment, manufacturing, testing and shipping, all of which are managed with assurance system strict quality.

The motion is converted into rotational motion: Even when the screw is preloaded, it can still maintain its smooth motion characteristics.

|

|

| Video |