AUTOMATIC EDGE BANDER

Olimpic k 800 is suitable for the company that produces high quality panels with many variations, thanks to the many automations making a work change automatic and free of errors. The K 800 edge bander manufactures at the same time up to 15% of panels more due to the 18 m/min increased working speed also when rounding and to the automatic function for the optimisation of the distance between panels.

- :K-800

- :Italy

- :12 tháng

- :Call

- :

AUTOMATIC EDGE BANDER

Model: K-800

|

Specifications

|

|

|

Panel thickness

|

0.4 – 8 mm (12mm opt)

|

|

Edge thickness

|

8 – 60 mm

|

|

Feed speed

|

12 – 18 m/min

|

|

Min. panels length

|

140 mm

|

|

BLOWER FOR PANEL CLEANING Optimum glue adhesion with the cleaning of the machined surface

INFRARED CERAMIC LAMP (OPT) Improved glue adhesion due to heating of the surface to be glued

|

|

|

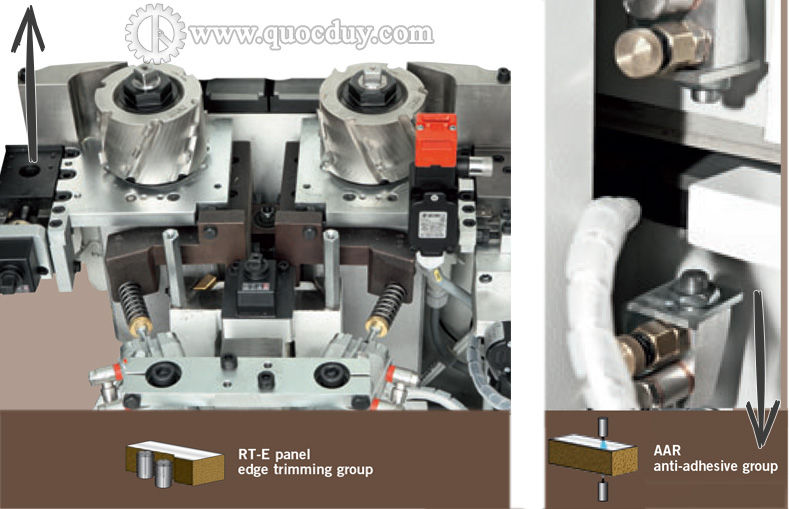

RT-E PANEL EDGE TRIMMING GROUP - Provides a perfect surface for gluing the edge

- ED SYSTEM high efficiency exhaust outlets

- Constant removal on the entire panel length with the copying devices kit (opt)

AAR ANTI-ADHESIVE GROUP (OPT)

It ensures the highest finishing quality by preventing the glue sticking to the upper and lower panel surfaces

|

|

|

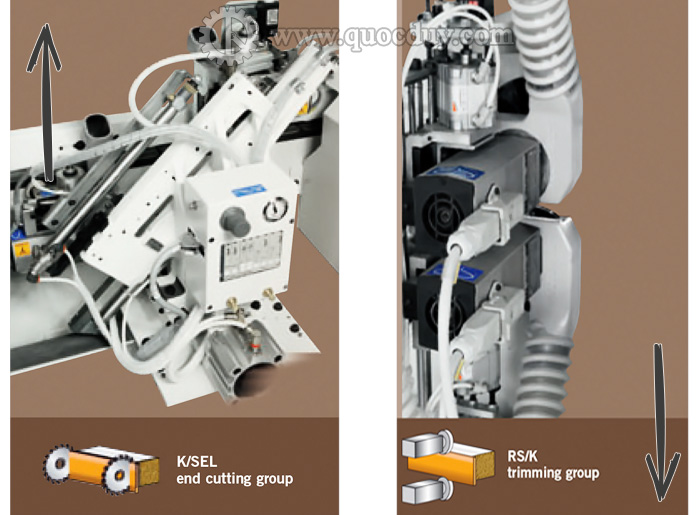

K/SEL END CUTTING GROUP - The best finishing quality thanks to the motors sliding on two independent guides

- Rapid set-up between straight and angled cutting with the automatic independent tilting of the motors (opt)

- Horizontal movement of the group in order to leave an exceeding edge that ensures an optimum finish of the Round group (opt)

RS/K IN-LINE TRIMMING GROUP - For the trimming of a solid wood edging or the removal of the exceeding edge thus providing the following chamfering operation

- ED SYSTEM high efficiency exhaust outlets

|

|

|

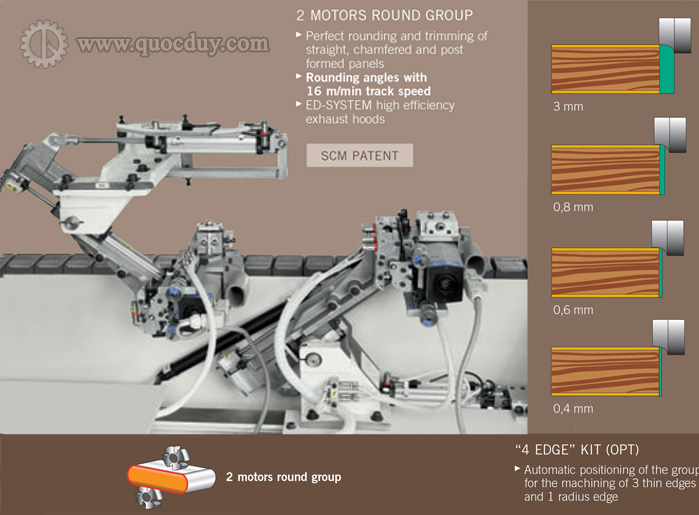

2 MOTORS ROUND GROUP - Perfect rounding and trimming of straight, chamfered and post formed panels

- Rounding angles with 16 m/min track speed

- ED-SYSTEM high efficiency exhaust hoods

|

|

|

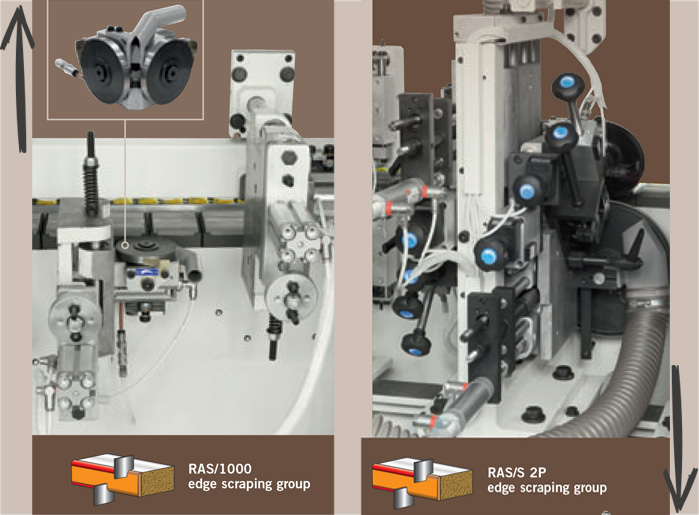

RAS/1000 EDGE SCRAPING GROUP (OPT) - Rapid and easy work changeover of the radius edge thanks to the substitution of the cutter-head, complete with rotating copying discs

- For the finishing of the PVC/ABS radius edge

- The group is complete with extraction hood with suitable container with filter for long chips

RAS/S 2P EDGE SCRAPING GROUP (OPT)

- Automatic work changeover of the radius edge through the two tool pneumatic positions

- For the finishing of the PVC/ABS radius edge

- The group is complete with large dimensioned extraction hood with suitable container with filter for long chips

|

|

|

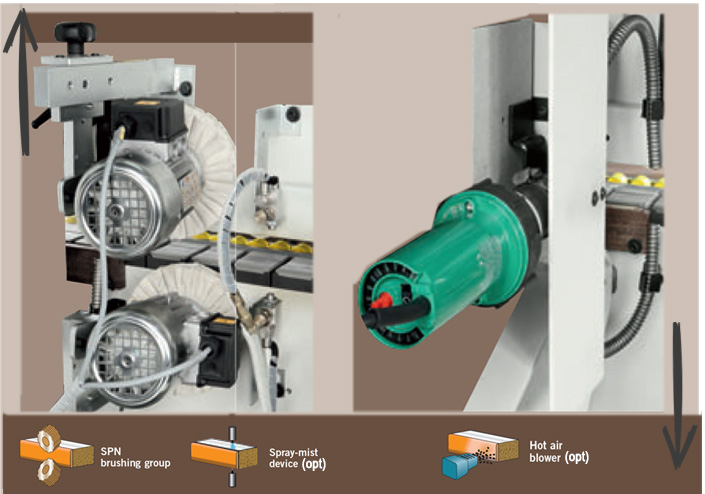

SPN BRUSHING GROUP (OPT)

Allows panel cleaning and polishing Easy adjustment with the hand wheel supplied with the group

SPRAY-MIST DEVICE FOR EDGE FINISHING (OPT) It improves the panel cleaning and the polishing of the PVC/ABS edge

HOT AIR BLOWER FOR PVC/ABS EDGES (OPT)

It reactivates the colour of the PVC/ABS edges

|

|

| Video | |