AUTOMATIC SINGLE-SIDED EDGE BANDING MACHINES

AUTOMATIC SINGLE-SIDED EDGE BANDING MACHINES

Model: AKRON-1100

| Structures | |

|

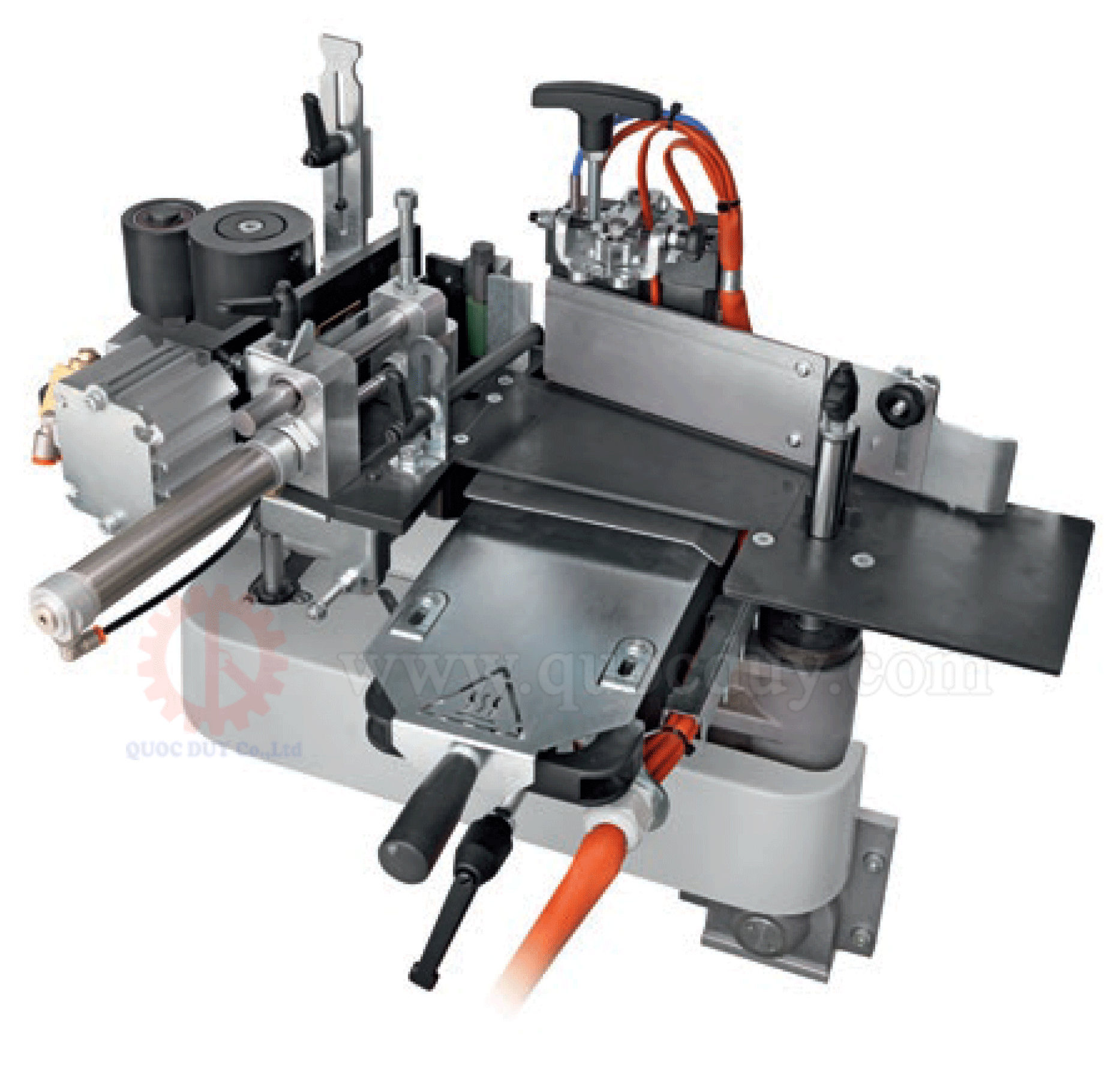

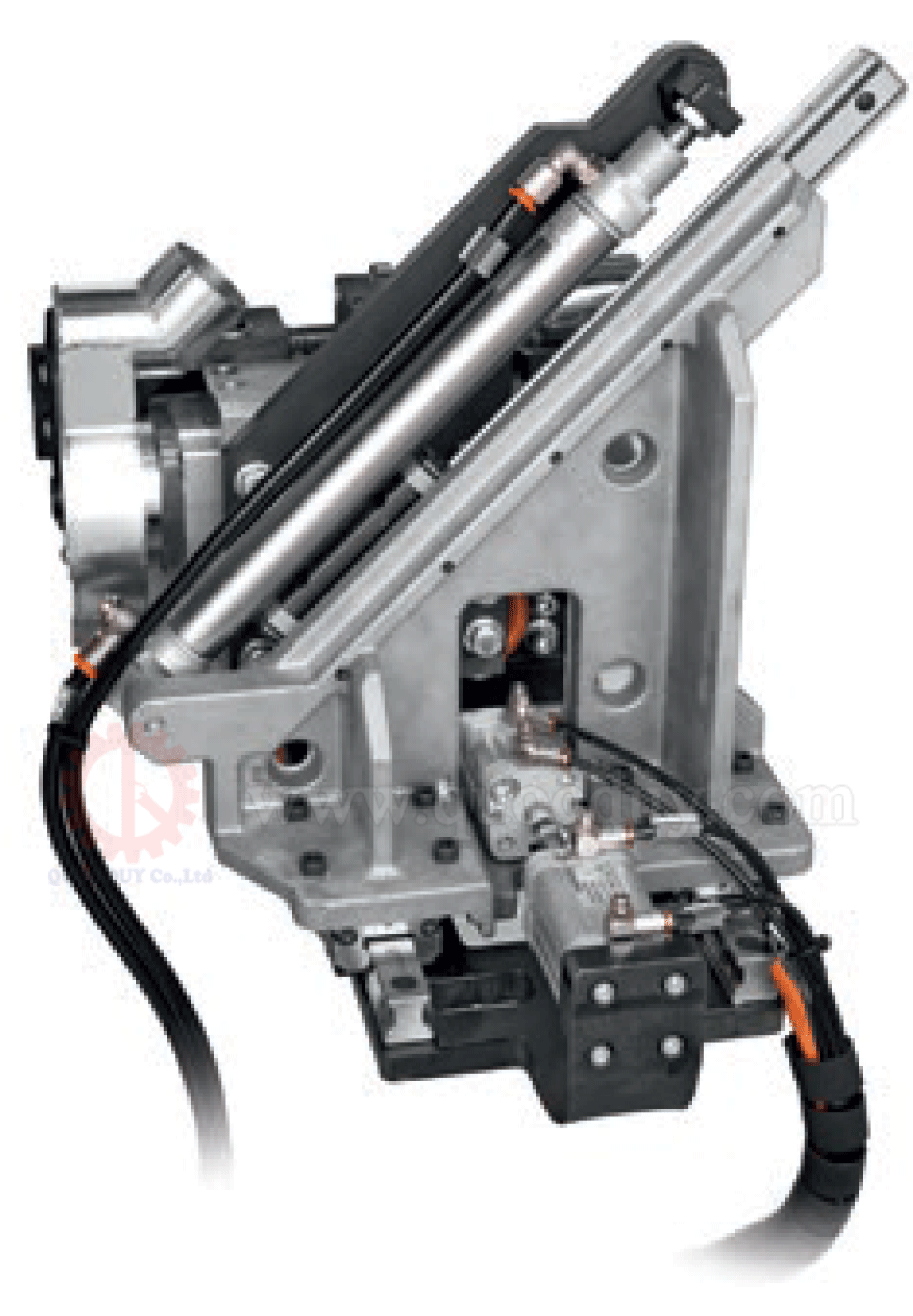

Perfect finish, due to the 2-motor Pre-milling unit with automatic intervention. |

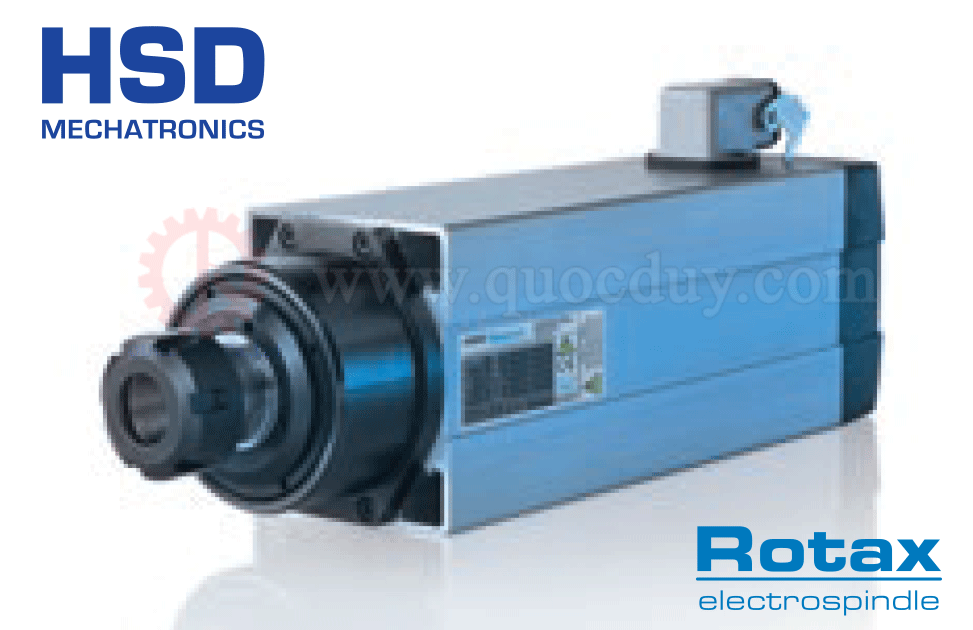

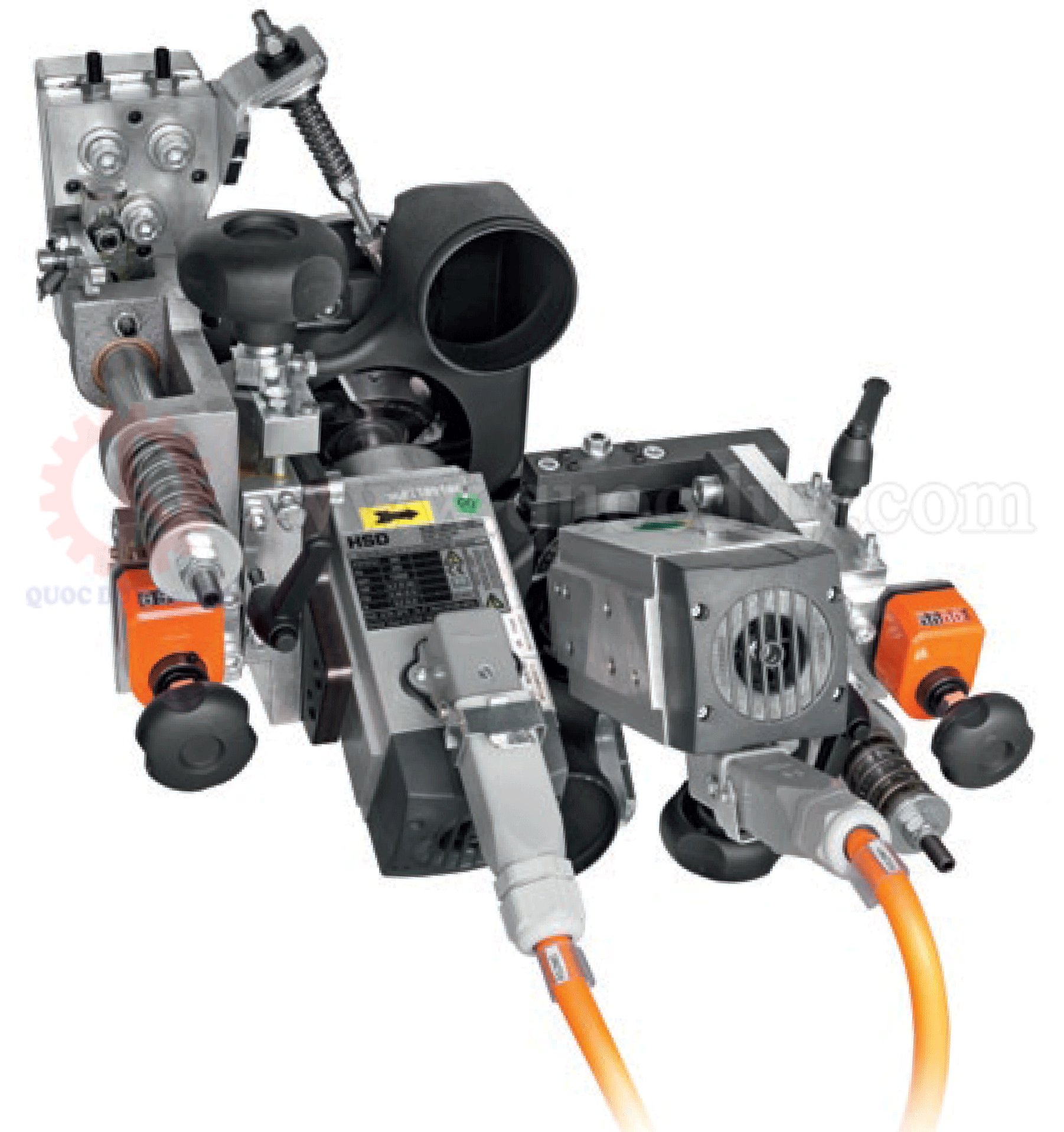

| As standard, Akron uses only the electrospindles of the exclusive Rotax range on all the machines. These are electrospindles of the highest quality, designed and made by HSD (a leader in this sector); they guarantee optimum power, compact dimensions, and extremely high finishing standards. |  |

|

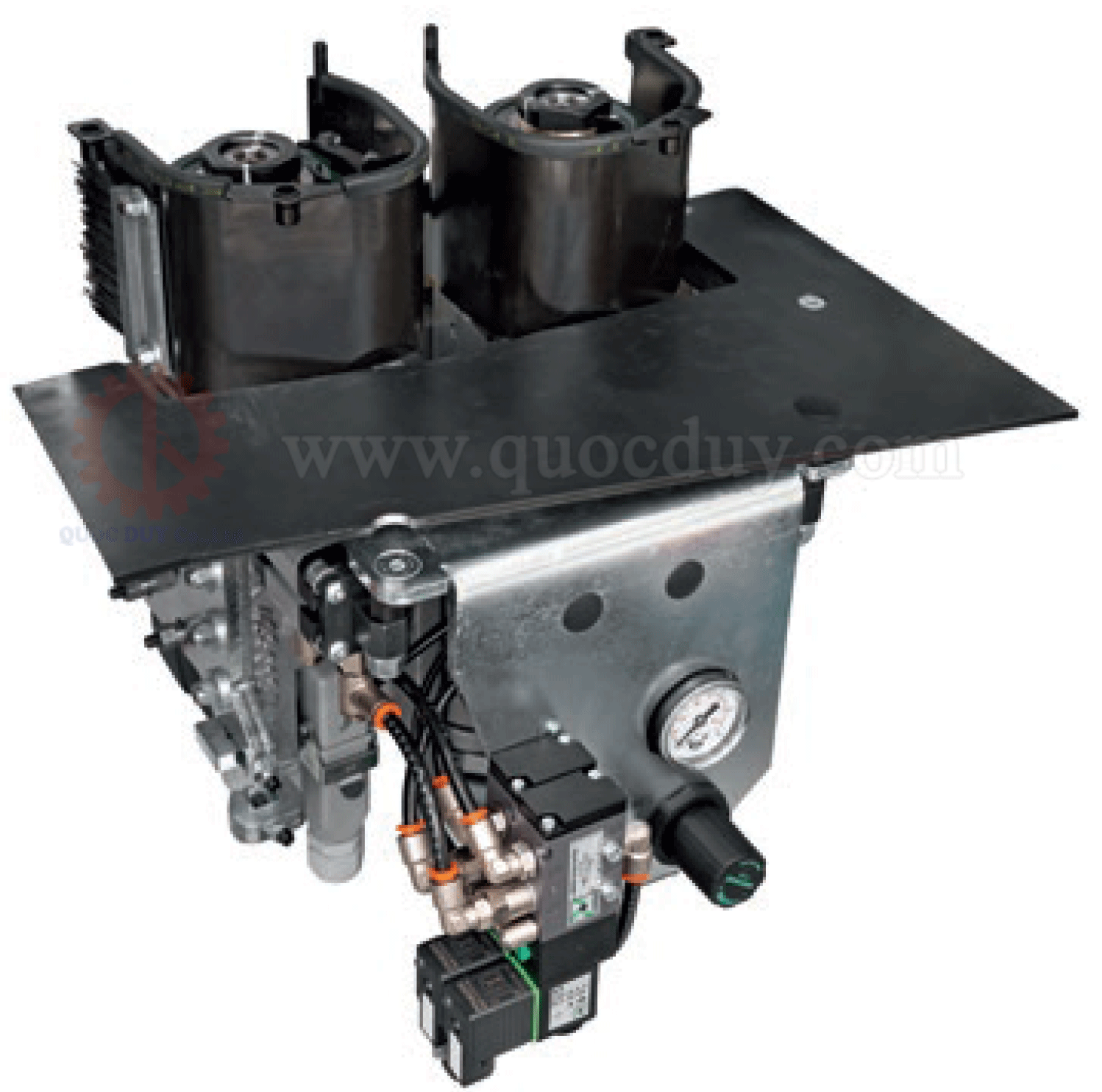

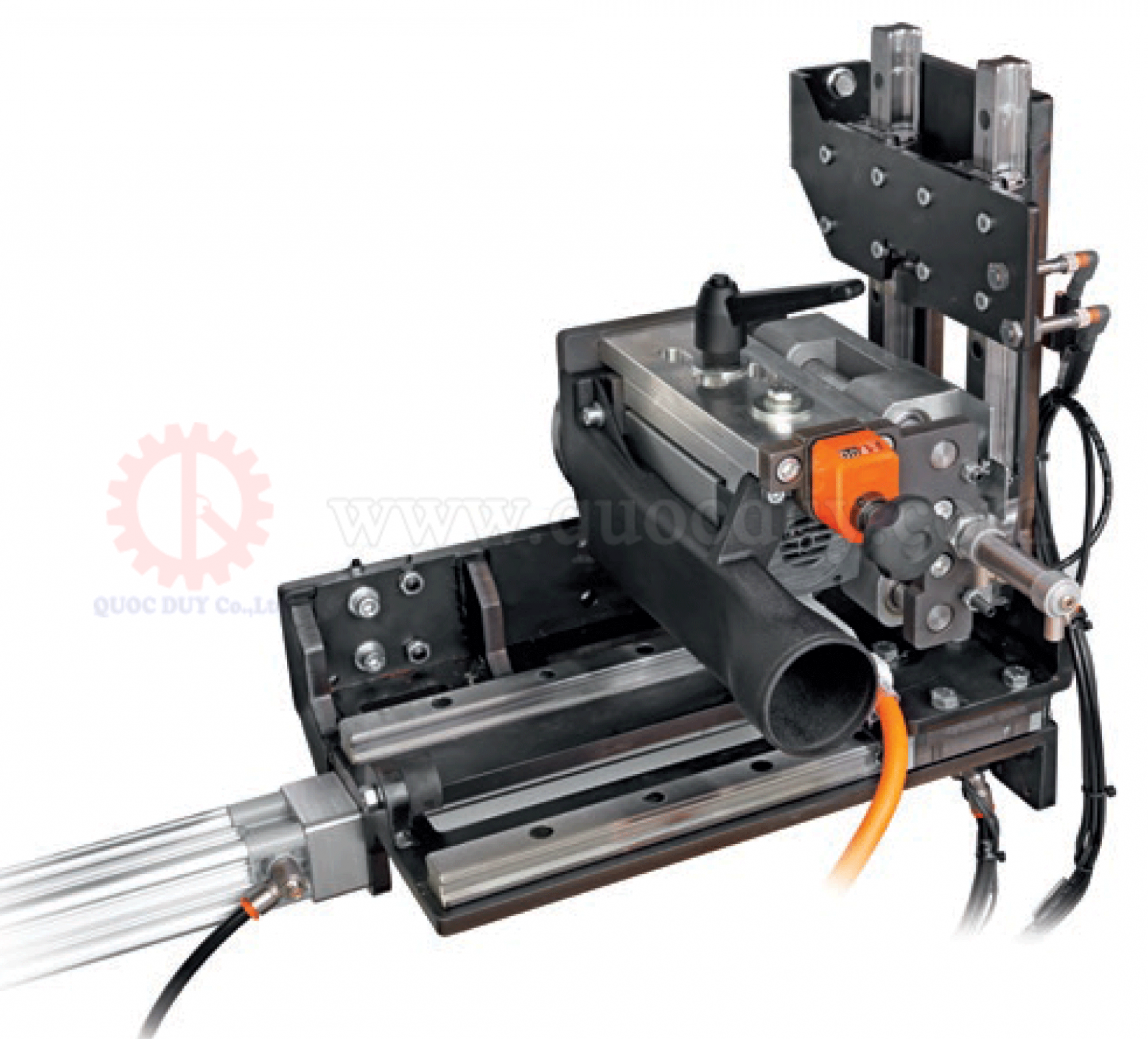

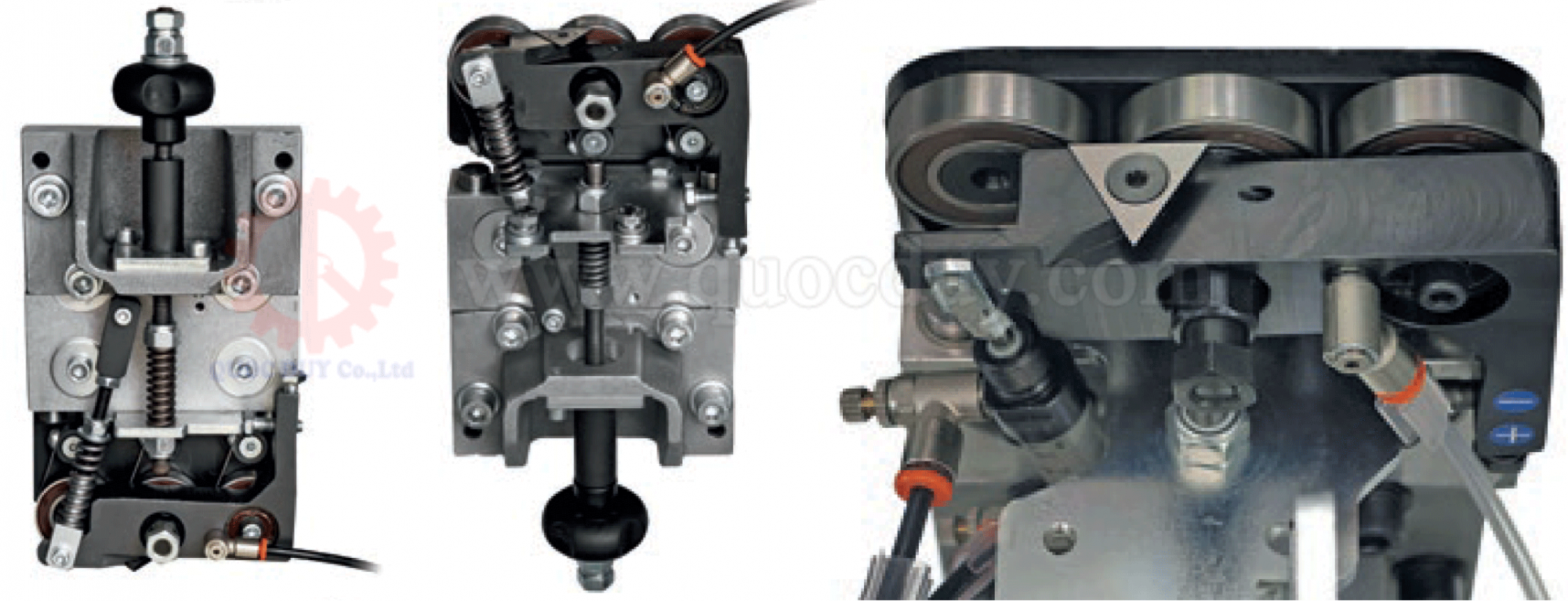

Gluing unit for the automatic application of edging in rolls or strips, from 0.4 to 5mm. The removable glue bowl ensures very easy maintenance and the possibility to use different glue colours to suit the panel.

|

| Reliability and cutting accuracy, due to the End Trimmer that removes excess edge at the front and rear of the panel |  |

|

Fine trimming unit for trim cutting the edge banding strip, complete with 2 high-frequency motors. |

| A rigid structure and linear guides with ball blocks guarantee excellent stability and machining precision over time |  |

|

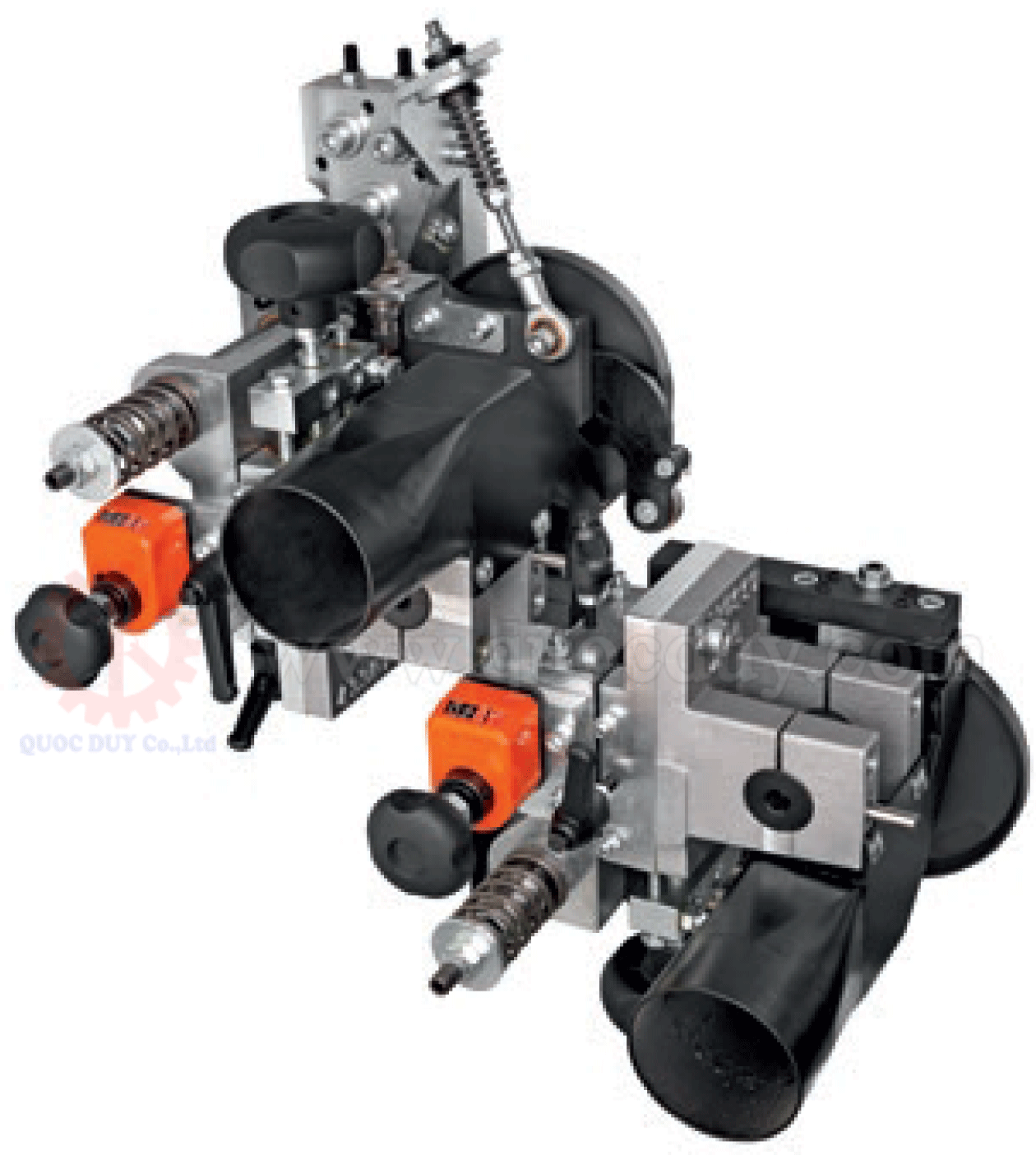

The edge-scraper unit eliminates the surplus on the top and bottom of the edgebanding strip, from previous machining operations |

|

The Glue Scraper removes excess glue from the top and the underside of the panel |

|

|

Buffing unit for cleaning and polishing the edge and panel |

| The Grooving Unit creates grooves and performs milling operations on the underside of the panel |  |

|

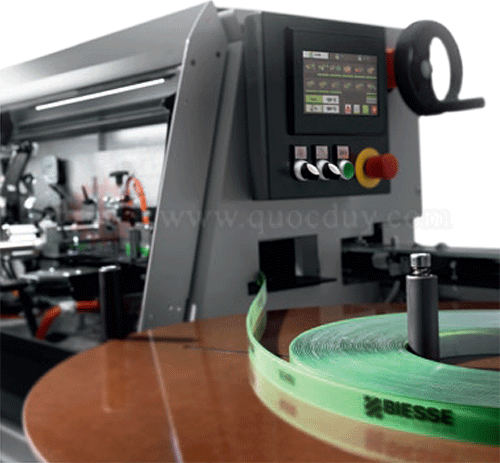

New 7-inch SMART TOUCH control - the only one of its kind on the market. Simple, instant programming within reach of all users, thanks to the touch screen control panel |

| Specification | |

| Speed feed | 9 m/min |

| Panel height | 8-50mm |

| Edgebanding thickness | 3-5 mm |