CNC DOUBLE SPINDLE HORIZONTAL BORING MACHINE

CNC DOUBLE SPINDLE HORIZONTAL BORING MACHINE

Model: SMCK 3000/2 CNC

|

Features

|

|

|

- The machine performs a variety of machining such as: drilling round holes to create cam connections, milling grooves, running curved profiles, milling negative mortises, hitting positive mortises, etc.

- Equipped with 2 machining heads, you can choose the right tool for processing needs

- No need to repeat the calibration for machining positions

- Product length sensor

- Infrared scans on the surface of the board to determine the hole from which to drill a horizontal hole to connect the linkage cam

- Besides the pink scan, the machine is also equipped with a barcode scanner to read and process according to the preset program

- Automatically get coordinates 0, there are 2 working areas, the machine will automatically take the first point of the board as coordinate 0

- Especially: with automatic Z-axis sensor up and down, helping the machine work in the X Y Z direction effectively, all 3 axes are controlled by a 0.75 kw servo motor for very high speed

|

|

|

Specifications

|

|

|

Drilling hole depth

|

: 0 - 35 mm

|

|

Working thickness

|

: 10-35 mm

|

|

X axis stroke

|

: 3000 mm

|

|

Y axis stroke

|

: 70 mm

|

|

Z axis stroke

|

: 70 mm

|

|

Spindle speed

|

: 18000 rpm

|

|

Spindle motor

|

: 3.5 kw x 2

|

|

X axis servo motor

|

: 0.75 kw

|

|

Y axis servo motor

|

: 0.75 kw

|

|

Z axis servo motor

|

: 0.75 kw

|

|

Total power

|

: 9.25 kw

|

|

Voltage

|

: 380V/ 50Hz

|

|

Working air pressure

|

: 0.6 Mpa

|

|

Machine size

|

: 3500 x 1750 x 1250 mm

|

|

Machine details

|

|

|

CONTROL DISPAY

|

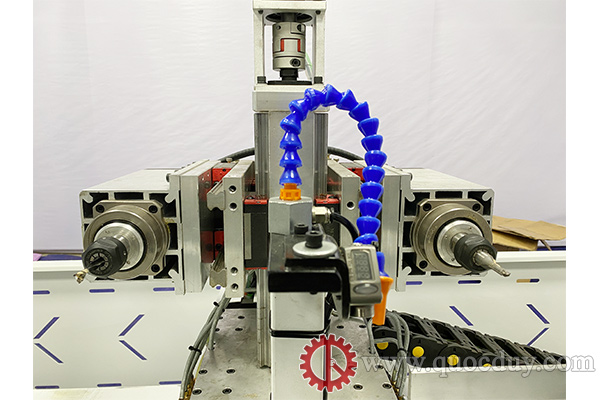

PROCESSING

|

|

LASER PROBE

|

AUTOMATIC LUBRICATING OIL SUPPLY

|

|

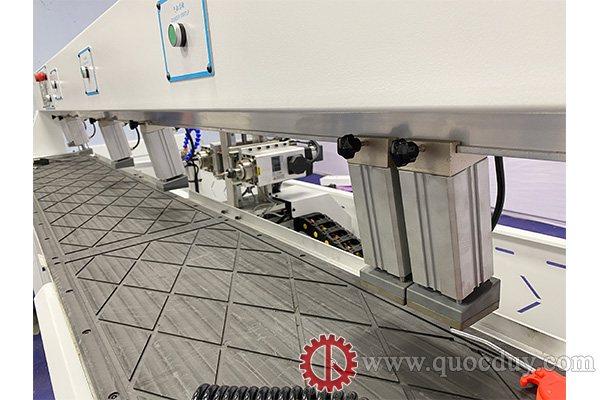

3 – TABLE WORKING

|

MOTOR SERVO

|

|

ELECTRICAL PROTECTION RUBBER

|

BARCODE SCANNER

|