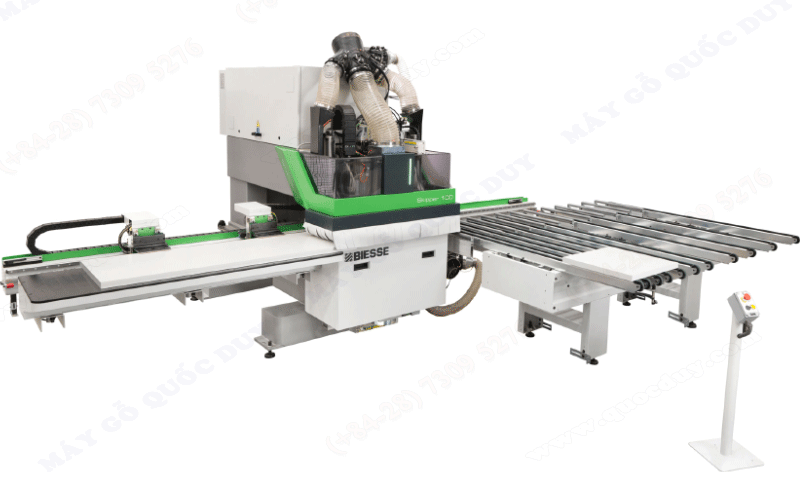

CNC ROUTER AUTOMATIC BORING

CNC ROUTER AUTOMATIC BORING

MODEL: SKIPPER 100

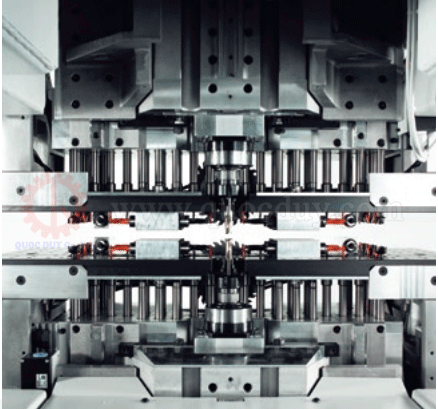

| Structure | |

|

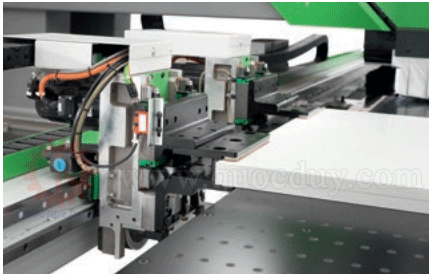

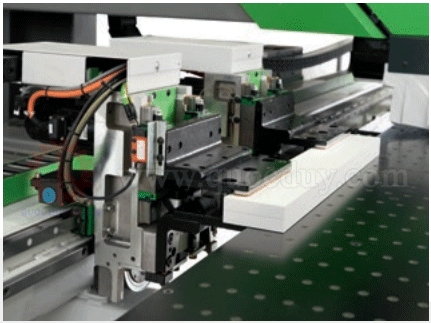

Total flexibility when machining panels of any size and thickness. Simultaneous machining operations from above and below in real time, without any interruptions and without the need to pass the panels through the machine more than once. To start, you just need the work program; no tools, adjustments or tests are necessary because the panel is clamped with automatically positioned vices |

|

To start, you just need the work program; no tools, adjustments or tests are necessary because the panel is clamped with automatically positioned vices.

|

|

|

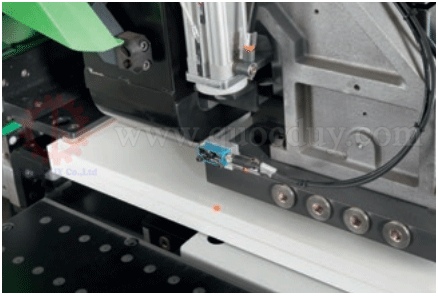

The size detection system measures the exact X-Y panel dimensions in real time, automatically adapting the machining positions |

|

Skipper can activate up to 82 tools in real time, and reach movement speeds of more than 100m/min in absolute safety

|

|

|

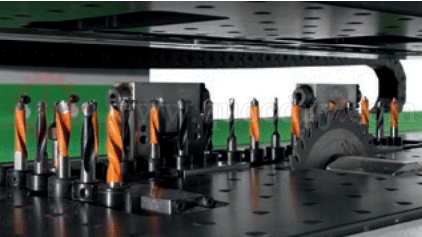

Easy, quick tooling of both operating sections |

|

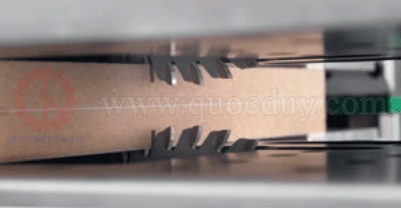

Blade units for channels in the X direction. |

|

|

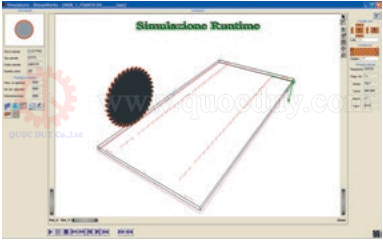

An extremely powerful yet user-friendly operator interface that allows quick decisions and automatically optimises the cycle on the basis of the tools available, to minimise work times |

| Specification | |

| Machinable panel length (Skipper 100 L) | 90 - 3000 mm |

| Machinable panel length (Skipper 100 S) | 90 - 2500 mm |

| Width of machinable panels | 70 -1000 mm |

| Thickness of machinable panels | 8 - 60 mm |

|

Vertical boring spindles (above+below)

|

29 + 29

|

| Boring spindle rotation speed (max) | 4000 rpm |

|

Horizontal boring spindles in X (above+below)

|

8 + 8

|

|

Horizontal boring spindles in Y (above+below)

|

2 + 2

|

|

Electrospindle 3.5 kW (above+below)

|

1 + 1

|

| Electrospindle rotation speed (min-max) | 7000 -18000 rpm |

| Blade unit diam. 150mm (above+below) | 1.7 kW 1+1 |

| Blade unit diam. 160mm (above+below) | 3.5 kW 1+1 |