EDGE SANDING AND COATING AUTO PRODUCTION LINE

This edge sanding and vacuum painting auto sanding line is combined of 2 sets of edge sander and 2 sets vacuum painting system and drying unit to finish sanding and painting at one time.

- :MMP-W4C2-T2G4

- :Semac - Quoc Duy

- :12 tháng

- :Call

- :

EDGE SANDING AND COATING AUTO PRODUCTION LINE

Model: MMP-W4C2-T

|

Process

|

|

|

Feeding→ Blowing dust → UV Paint → UV drying→ sanding → sanding→ Blowing dust→ UV Paint → UV drying → sanding → sanding → sanding →Feeding out.

|

|

|

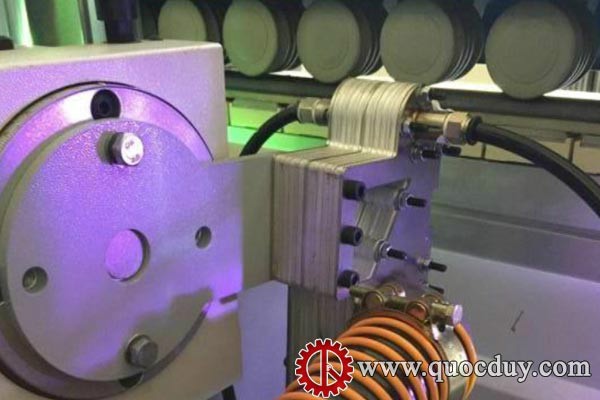

Vacuum painting head Illustration:

- Use special technology and production process,, Has high efficiency, save energy, protect the environment, high speed, feature, suitable for straight edge and edge with shapes. Develop accordingly module as edge shape, painting gun make Sure Small box full with paint material like fog, edge pass this box, Fog type paint will stick to edge surface. Speed can be up to 15-24m/min, and paint amount range Is bigger, to get satisfying painting function.

|

|

|

Vacuum paint box:

|

|

|

Vacuum painting function: - Vacuum painting can paint special-shaped edge, and get neat painting boundary line; - No flow and accumulation; - The painting quantity with a larger range can be realized, and the painting quantity is 15-80g/square, and it is easy to realize. - The same vacuum painting system can be equipped with two vacuum painting heads, which can work at the same time and save energy. - One painting can replace 2-3 times roll coating effect without delamination. |

|

|

Drying system: - Drying equipped with 4 different element lamp 2.4*4, each lamp can be installed with gallium, mercury, halogen lamp at will, without changing other configuration and modifying parameters; - With stepless dimming function, the light source energy can be adjusted at will, and the operation is simple and fast. - With automatic standby function, the energy consumption such as drying will stop and close automatically when the drying time exceeds the set time and does not work, thus greatly realizing the waste of electricity. - The shutter lampshade is installed, and the shutter lampshade opens automatically when the board passes, and closes automatically after completion. - 60% energy saving than ordinary drying. - It can be quickly started to work, time is 1 minute. |

|

|

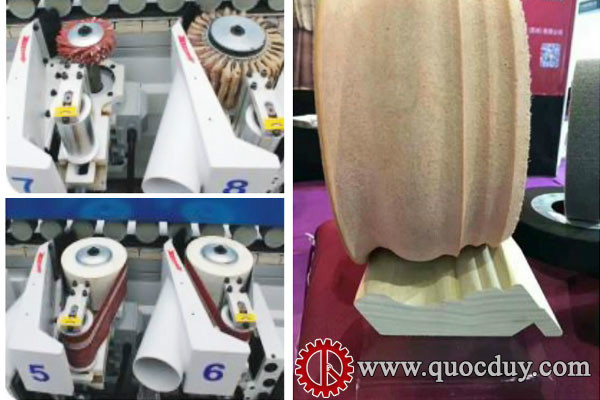

Multifunction sand W part:

Mark W part is multifunction sand head,maximum sanding thickness 100mm;sanding linear speed can be controlled by frequency motor 0-12m/s; belt length 840mm; sand head matches worldwide common standard sanding wheels, has abrasion automatic compensation function;can ODM sanding wheels as per the shape of work piece, comprehensively sanding irregular edges and surfaces; and have automatic flexible in and out function to protect front and end of work piece from painting material, can be adjusted from +90° to -90°;is mainly used to sand and polish for wide work piece, such as solid wood, MDF, Aluminum sheet etc. |

|

|

Multifunction sand W

|

|

|

Power

|

: 1.5kw

|

|

Air pressue

|

: 0.6-0.8 Mpa

|

|

Specs

|

: #320/#400

|

|

Multifunction sand T

|

|

|

Power

|

: 3KW*2

|

|

Air pressue

|

: 0.6-0.8 Mpa

|

|

Specs

|

: 15-80g/ m2

|

|

Sấy UV G

|

|

|

Specs

|

: 0-24m/phút

|

|

Power

|

: 3KW*4

|

|

Air pressue

|

: 0.6-0.8 Mpa

|

|

Specifications

|

|

|

Max.width of workpiece

|

: 2000mm

|

|

Min.width of workpiece

|

: 60mm

|

|

Max.depth of workpiece

|

: 80mm

|

|

Height of working table

|

: 860mm

|

|

Feeding speed

|

: 0-24mm

|

|

Conveyor motor

|

: 1.5kw

|

|

Speed motor

|

: 1400 vòng/phút

|

|

Dedusting motor

|

: 0.37kw

|

|

Vacuum painting power

|

: 3kw *2

|

|

UV dryer power

|

: 3kw*4

|

|

Total power

|

: 28kw

|

|

Vacuuming mouth

|

: Ø100mm

|

|

Net weight

|

: 1600kg

|

| Video | |

\