- production line

- WOODWORKING MACHINE

- CNC MACHINE

- SAWING MACHINE

- EDGE BANDING MACHINE

- DRILLING MACHINE

- SANDING MACHINE

- PLANER MACHINE

- TENONER MACHINE

- SHAPING MACHINE

- LATHE MACHINE

- ENGRAVING MACHINE

- FINGER JOINT AND CLAMP CARIER

- PRESSING MACHINE

- VENEER MACHINE

- GRINDING MACHINE

- DOWEL MAKING MACHINE

- POWER FEEDER

- UV COATING MACHINE

- GLUE SPREADER

- WOOD PALLET MAKING MACHINE

- EMBOSSING MACHINE

- WOOD BARKING MACHINE

- DUST COLLECTOR

- AIR COMPRESSOR

- AUXILIARY MACHINE

- Máy cắt bọ eke

- Máy đa chức năng

- HARD WARE

- FINISHING LINE

- USED MACHINE

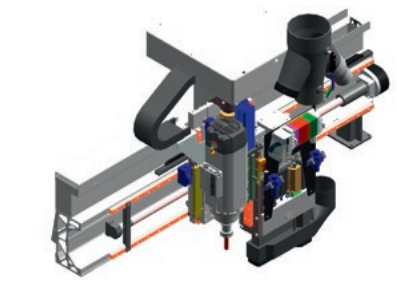

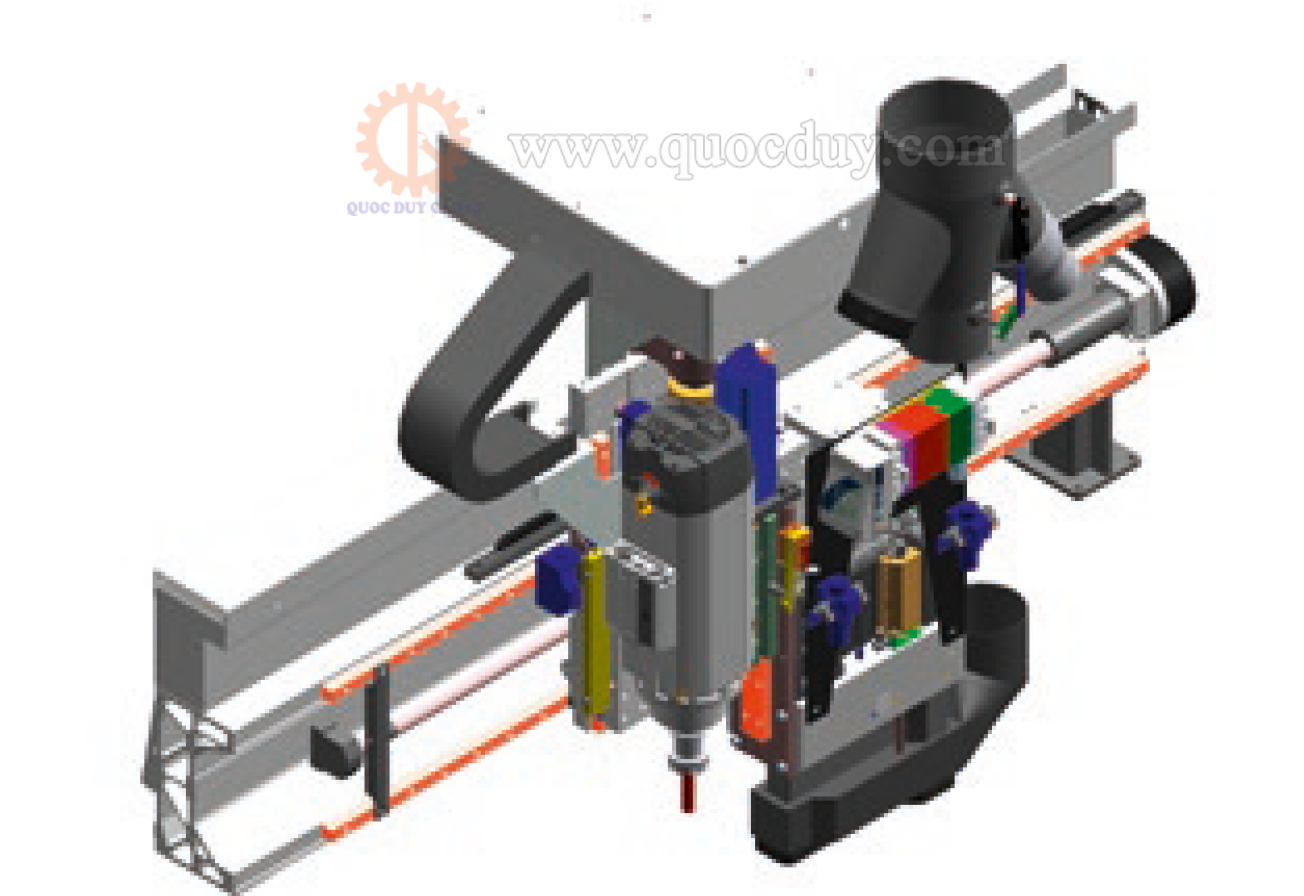

BORING AND INSERTING MACHINES

BORING AND INSERTING MACHINES

Model: INSIDER DOOR

| Feature | |

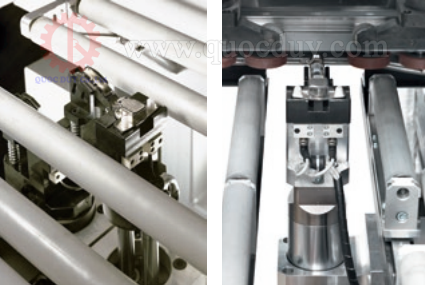

Boring from below with hinge chuck

|

Boring from above and/or below for handles, knobs, bumpers, etc

|

Insertion of hinges and bumpers

|

Horizontal boring for anuba hinges

|

|

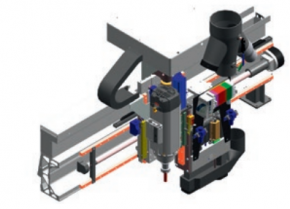

Machine structure

|

|

Lower boring head with 7 spindles on the Y axis and 3 on the X axis.. |

Upper beam unit complete with boring head with 7 spindles on the Y axis and 3 on the X axis, and a milling unit of 5.5 kW |

|

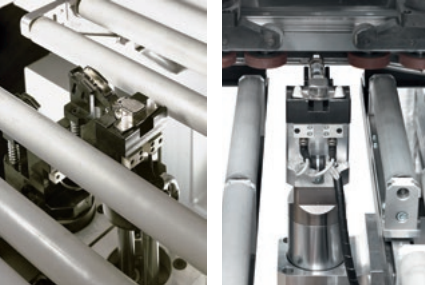

Insertion operations are precise, reliable and constant thanks to the press-fit pick-up system that operates on a fixed beam. Up to 3 different types of hinge can be inserted. |

The insertion unit is powered by a vibrating feeder (maximum 2) and a vertical gravity feeder to provide the machine with the greatest possible autonomy and minimise the need for operator intervention. |

|

|

The pressers secure the panel during machining without scratching it and without compromising machine productivity |

|

The user interface PC with Windows operating system is perfectly integrated with management software packages and network systems available on the market. Many functions such as assisted graphic editor, parametric programming, machining head graphic tooling, the import of files in DXF and CID format - and many others - enable the machine to be used in an easy, intuitive way |

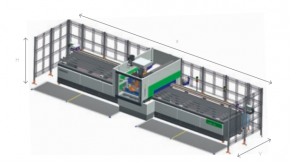

| Specification | ||

|

|

Insider KB

|

Insider FB

|

| Machine length |

7875 mm

|

7875 mm

|

| Machine width |

3900 mm

|

3180 mm

|

| Machine height |

2000 mm

|

2000 mm

|

|

Work table height

|

900 mm

|

900 mm

|

|

Spindle rotation speed

|

6000 rpm

|

|

|

X/Y/Z axis speed

|

135/100/25 rpm

|

|

|

Actual working field length

|

250-2500 mm

|

|

|

Actual working field width

|

97-800 (240-800 with hinges inserted)

|

|

|

Actual working field height

|

13-30mm

|

|

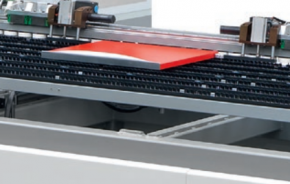

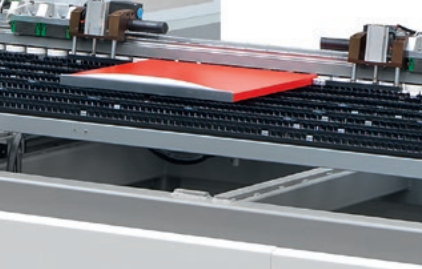

The panel handling system with controlled clamps has been specifically designed to prevent any positioning errors and to better handle the machining of delicate panels.

The panel handling system with controlled clamps has been specifically designed to prevent any positioning errors and to better handle the machining of delicate panels.