- production line

- WOODWORKING MACHINE

- CNC MACHINE

- SAWING MACHINE

- EDGE BANDING MACHINE

- DRILLING MACHINE

- PLANER MACHINE

- SANDING MACHINE

- TENONER MACHINE

- SHAPING MACHINE

- LATHE MACHINE

- ENGRAVING MACHINE

- FINGER JOINT AND CLAMP CARIER

- PRESSING MACHINE

- GRINDING MACHINE

- VENEER MACHINE

- DOWEL MAKING MACHINE

- POWER FEEDER

- UV COATING MACHINE

- GLUE SPREADER

- WOOD PALLET MAKING MACHINE

- EMBOSSING MACHINE

- WOOD BARKING MACHINE

- DUST COLLECTOR

- AIR COMPRESSOR

- AUXILIARY MACHINE

- Máy cắt bọ eke

- Máy đa chức năng

- FINISHING LINE

- HARD WARE

- USED MACHINE

CNC HOUSING MACHINING CENTRES FOR ROUTING AND DRILLING

CNC Housing Machining Centres for routing and drilling the flexibility at 360°. The 5 axes cnc machining centre for the company that requires flexible and high quality workings. Reliability and productivity guaranteed by advanced solutions, such as the compact and powerful "Prisma 5" electrospindle with BEL.TECH technology (Belt technology system), the high performance RO.AX (Rotoaxial spindle technology) drilling heads and the bumpers safety system, for a quick and efficient machining, in total security.

CNC HOUSING MACHINING CENTRES FOR ROUTING AND DRILLING

Model: TECH Z5

|

ADVANTAGES

|

||

|

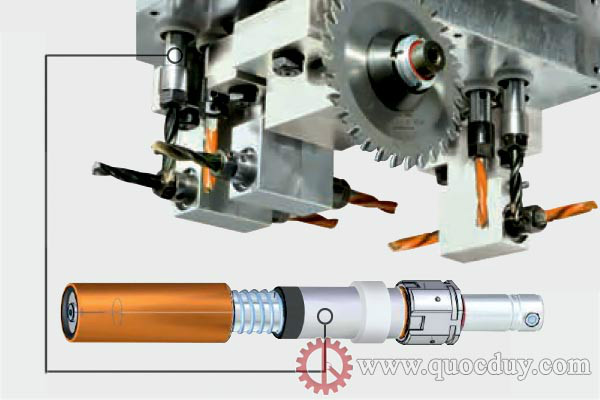

“PRISMA 5” ELECTROSPINDLE: SUPERIOR TECHNOLOGY FOR MACHINING WITH 5 AXES   Reduced maintenance, maximum flexibility and optimal finishing quality with the BEL.TECH technology (Belt technology system), the belt transmission system which eliminates vibration and heat from tools to the motor. This system (in use on the spindle for machining metals) due to the compact structure, allows easy operations in limited spaces. The mechanical locking of the spindle in the vertical position, transforms the unit into a perfect 3 axis operation.

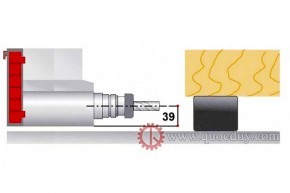

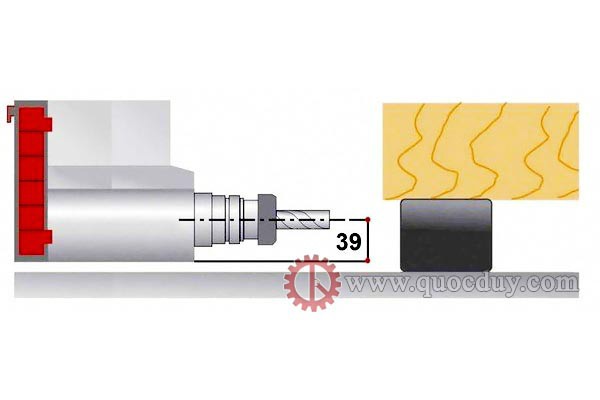

“BUMPERS”: THE PERFECT COMBINATION OF SAFETY AND PRODUCTIVITY   The “bumpers” safety system is the only one that can fully exploit the potential of machining centres, without placing restrictions or constraints on the use of the machine: maximum productivity, ease-of-use, more compact dimensions and guaranteed safety. RO.AX SPINDLE: FOR PERFECT BORING

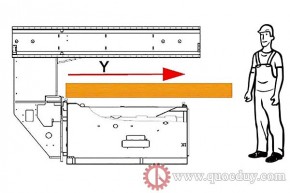

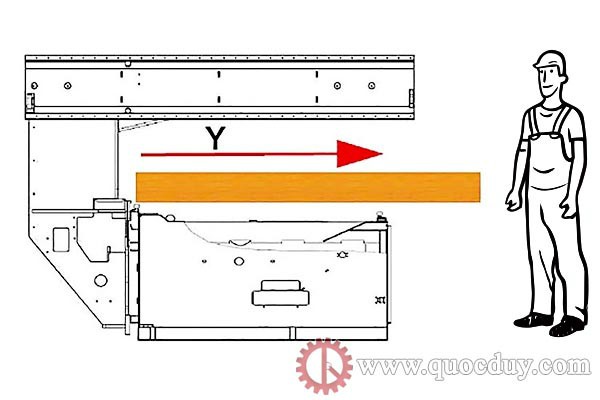

Zero play during machining with the new RO.AX technology (Rotoaxial spindle technology), the most efficient spindle on the market with rotation speeds up to 8000 rpm to configure the machine with different boring units from 7 to 50 independent spindles, for customers demanding high levels of boring. CANTILEVER STRUCTURE: UNIQUE AND EASY TO USE   The only structure that allows the loading of components along the “Y” axis far larger than the working capacity of the machine. |

||

|

SPECIFICATIONS

|

||

|

Model

|

z5-31

|

z5-52

|

|

Axes

|

||

|

Working area along X-Y-Z axis

|

3050 - 1550 - 160 mm

|

5200 - 1550 - 160 mm

|

|

Panel length along Y axis

|

1550 mm

|

1550 mm

|

|

Panel length (for alternated work process)

|

1390 mm

|

2460 mm

|

|

Vectorial speed X-Y axes (optional)

|

83 m/min

|

83 m/min

|

|

Boring head

|

||

|

Vertical spindles up to

|

18 (10X/4+4Y) - 8000 rpm

|

18 (10X/4+4Y) - 8000 rpm

|

|

Horizontal spindles up to

|

8 (4X / 4Y) - 8000 rpm

|

8 (4X / 4Y) - 8000 rpm

|

|

Integrated blade in X

|

Ø125mm – 10000rpm

|

Ø125mm – 10000rpm

|

|

Electrospindle

|

||

|

Standard motor power (S6)

|

12 (16,5) kW (Hp)

|

12 (16,5) kW (Hp)

|

|

Max. speed

|

24000 rpm

|

24000 rpm

|

|

Tool changer on the carriage in X / base

|

16 / 10 places

|

16 / 10 places

|

|

VIDEO

|

||