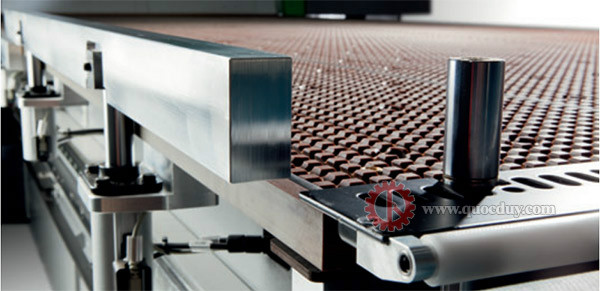

- production line

- WOODWORKING MACHINE

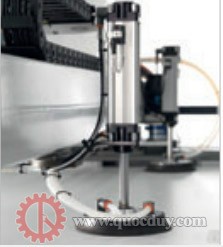

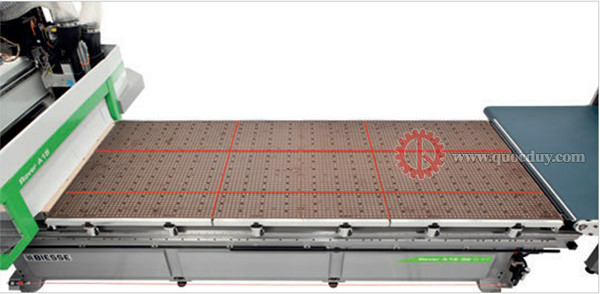

- CNC MACHINE

- SAWING MACHINE

- EDGE BANDING MACHINE

- DRILLING MACHINE

- SANDING MACHINE

- PLANER MACHINE

- TENONER MACHINE

- SHAPING MACHINE

- LATHE MACHINE

- ENGRAVING MACHINE

- FINGER JOINT AND CLAMP CARIER

- PRESSING MACHINE

- GRINDING MACHINE

- VENEER MACHINE

- DOWEL MAKING MACHINE

- POWER FEEDER

- UV COATING MACHINE

- GLUE SPREADER

- WOOD PALLET MAKING MACHINE

- EMBOSSING MACHINE

- WOOD BARKING MACHINE

- DUST COLLECTOR

- AIR COMPRESSOR

- AUXILIARY MACHINE

- Máy cắt bọ eke

- Máy đa chức năng

- HARD WARE

- FINISHING LINE

- USED MACHINE

Quoc Duy Engineering & Machinery Co., Ltd

OFFICE

Add: 11/19 Nguyen Oanh Str., Ward.10, Go Vap Dist., HCMC

Tel: (+84-28) 7309 5276

Fax: (+84-28) 3989 0036

Email: [email protected]

Website: www.quocduy.com

FACTORY

Add: 401 To Ngoc Van Str., Thanh Xuan Ward. , 12 Dist., HCMC

Tel: (+84-28) 7309 5276

Fax: (+84-28) 3989 0036

Email: [email protected]

Website: www.quocduy.com