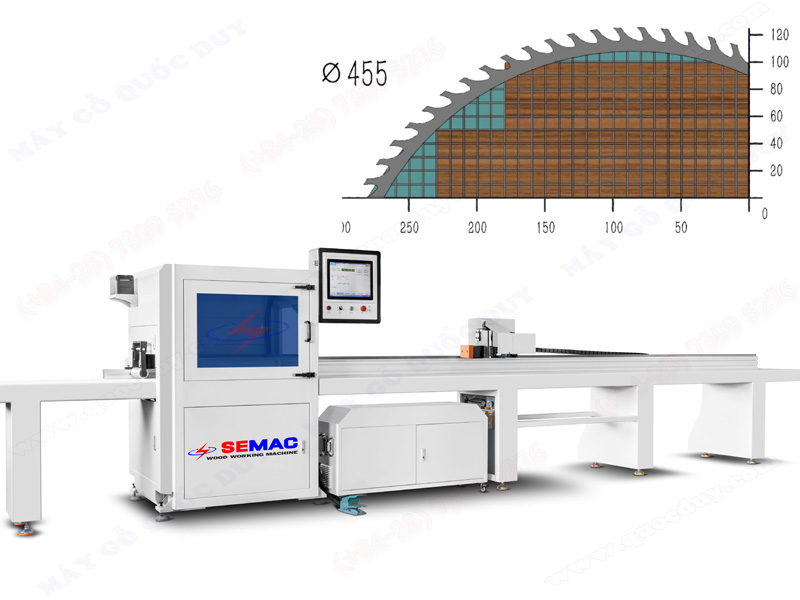

CNC OPTIMISING SAW MACHINE

CNC OPTIMISING SAW MACHINE

Model: SM-6

|

Optimal cut saw

|

|

|

- Working way: when the push rod back, scan the draw lines on the workpieces, and input the length data in the PC for the optimization. - Designation Priority: The designation length of workpieces in the cut list can be cut first, Priority can be given to materials in short supply in production line. - Fixed Cutting: Do not optimize, follow up the lít from up and down of the order list, it is suitable for the no defects materials. - Largest Value: Based on the prices in the list, software combines the most valuable cutting methods, which can maximize the utilization value of the material. - Defect cutting: The sawing position is marked on the wood by manually, and the equiment is automatiscally finds the line position ( this way working, only follow up the drawing lines cutting, not optimizing. Supporting excel file for the import order material, and support customize the form format. Cutting list can add barcode, and print barcode, two-dimensional code free setting. |

|

| Specifications | |

|

Working length

|

: 4000 mm ( option: 6000 mm)

|

|

Working width

|

: 10 – 230 mm

|

|

Working thickness

|

: 10 – 80 mm

|

|

Working cut area

|

: 250 x 30 mm

|

|

Scanning speed

|

: 80 m/min

|

|

Sawblade motor

|

: 10 Hp

|

|

Sawblade Dia.

|

: Ø 450 x 30

|

|

Dust collector dia.

|

: Ø 100 mm

|

|

Total installed power

|

: 11 Hp

|

|

Worktable height

|

: 900 mm

|

|

Line spacing

|

: Adjustable

|

|

Length scanned

|

: infrared light sensor

|

|

Defect scanned

|

: Fluorescence sensor

|

|

Net weight

|

: 1000 kg

|

|

Machine size

|

: 6700 x 1300 x 1600 mm

|

| Video | |