OPTIMIZING CUT OFF SAW

Ideal for finger jointing (for defect) materials and mass material preparation. Provides 3 ~ 5 times higher production rate than manual cut-off saws. Saves over 5% of wood materials.

- :CFS-200A

- :Taiwan

- :12 month

- :Call

- :

OPTIMIZING CUT OFF SAW

MODEL: CFS -200A

| Features | ||

|

- Ideal for finger jointing (for defect) materials and mass material preparation. - Provides 3 ~ 5 times higher production rate than manual cut-off saws. - Saves over 5% of wood materials. - Comprehensive safety guards for maximum operator protection. - Maximum feed speed is up to 150 M/min. - High cutting accuracy within ±1mm . - The control employs a touch screen for easy learning and operation. |

||

| Cutting Modes | ||

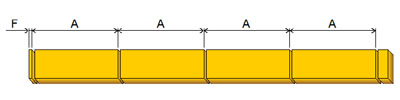

| 1. Fix length of cutting mode. |  |

|

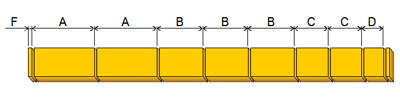

| 3. Sequential cutting mode. (10 sets of cutting sizes memory). |  |

|

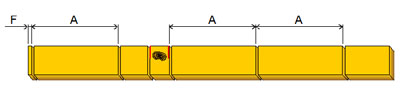

| 3. Marking lines cutting with double end trimming. |  |

|

| 4. Marking lines cutting and fixed length. |  |

|

| Specifications | ||

|

Saw motor

|

: 10HP

|

|

|

Feed motor

|

: 3.5 Kw

|

|

|

Saw spindle speed

|

50 HZ

|

: 4000 r.p.m.

|

|

60 HZ

|

: 4100 r.p.m.

|

|

|

Feed speed

|

: 15~150 M/min

|

|

|

Circular saw diameter

|

: ø455mm or ø505mm

|

|

|

Saw spindle diameter

|

: ø40mm

|

|

|

Height of bed (H)

|

: 900mm

|

|

|

Min. cutting size (L×W×H)

|

: 300×30×10mm

|

|

|

Cutting accuracy (for material length upt to 1m)

|

: ±1mm

|

|

|

Cutting accuracy (for material length upt to 3m)

|

: ±2mm

|

|

|

Air pressure

|

: 7~9 kg/cm2

|

|

| Video | ||