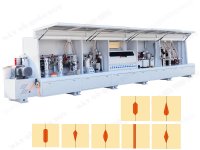

AUTOMATIC INCLINE AND STRAIGHT EDGE BANDING MACHINE

AUTOMATIC INCLINE AND STRAIGHT EDGE BANDING MACHINE

Model: COMBINE 12

|

Application

|

|

|

- Can stick all kinds of thread (splint): PVC, wooden splint, veneer, acrylic... - Widely used in interior products without handles: handles next to kitchen cabinets, next to wardrobes, beside beds, tables and chairs... |

|

|

Features

|

|

|

- 45 degree inclined chamfer milling system. - The machine is designed with 2 glue pots: 1 pot of straight edge glue, 1 pot of inclined glue. - Milling to extract the glue thread before gluing at a 45 degree angle. - The operation to change the straight and slant paste mode only needs 1 touch operation. - Large screen working, displaying all machine parameters while the machine is in operation. Help workers easily adjust and change parameters accordingly. - Automatic oil pump system protects the machine during its operation. |

|

|

Functions

|

|

|

1. Pre-milling

2. Grooving on tape

3. Gluing at inclination surfac

4. Gluing ports at straight surface

5. Edge tapes pressing device

6. End trimming

7. Fine trimming 1

8. Rough trimming 2

9. Rough trimming 3

10. Corner trimming

11. Scraping

12. Buffing

|

|

|

Specifications

|

|

|

Workpiece thickness of inclined

|

: 10 – 25 mm

|

|

Workpiece thickness of straight

|

: 10 – 60 mm

|

|

Feeding speed

|

: 12 – 20 m/min

|

|

Edge banding tape thickness

|

: 0.4~3mm

|

|

Panel width

|

: ≥80 mm

|

|

Working air pressure

|

: 0.8 mpa

|

|

Motor power

|

: 12.5 kw

|

|

Voltage

|

: 380/220V 50Hz

|

|

Net weight

|

: 2200 kg

|

|

Machine size

|

: 6700×1100×1600 mm

|