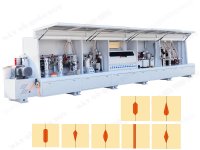

EDGE BANDING MACHINE

EDGE BANDING MACHINE

EXPERT 2600- 3600

| FEATURES | |

|

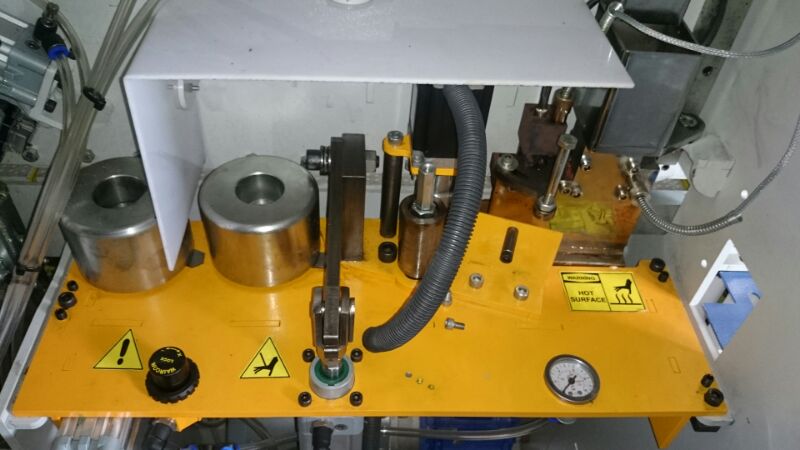

CONTROL SYSTEMS: Controls of all operating units such as opening- end cutting, half concave milling, thin-thick pvc automatic pass, normal soft mdf, item counter, quantities meter, pricing are carried out over plc colored touch screen. High frequency motors are controlled by convertors and includes emergency switches. Electronic systems are lidded and sealed to protect from dust etc. environments.

|

|

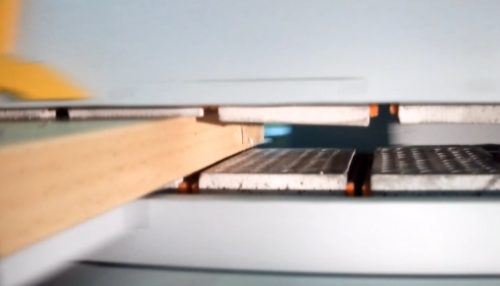

FEEDER: Designed in such a way that edge bandings shall be loaded from large scaled carrier bobbins.

|

|

Grooving With Angled Jumping (Optional): Sloped jumping input-output distance can be adjusted from plc colored touch screen. The diameter of saw is 80 X 4 mm (ops) SAFETY SYSTEMS: The electro pneumatic accessories of the machinery carries out the automatic cleaning of oils during operational period; in the event that phases and air are not enough, machinery protects itself and prevents the damage to its systems. Part controls the feed interval and notify about the malfunction on the plc colored touch screen. |

|

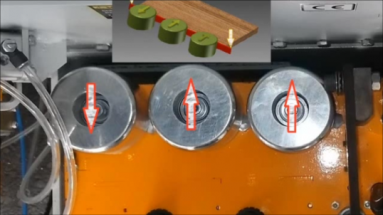

PRESSING ROLLERS: The proximity switch and plc controlled pneumatic system patented to HAKİ SABIR comprises of 3 rollers. Being gripping drive, the initial pressing carries out printing settings automatically. This is the only machine that does not apply pressure to the overplus that are in front and rear part of the material to be glued. .

|

|

SCRAPING GROUP: It is the only scraping unit which is patented to HAKİ SABIR, independent from each other, upper and lower radius, pneumatic and does not lead to blockage, by-pass. Can carry out automatic adjustment from 0.40 mm up to 2 mm. SOLVENT SPRAYING: It sprays the liquid that is used for cleaning of glue and polishing of banding surface.

POLISHING GROUP: It carries out the glazing and polishing the banding surface with the help of solvents, two separate 1500 d/min motors. |

| Specifications | ||

|

Model

|

Expert 2600

|

Expert 3600

|

|

Electrical Level

|

380-220 / 50hz

|

|

|

Nominal Current

|

18A

|

20A

|

|

Edge Material Thickness

|

0.4-3mm

|

|

|

Board Thickness

|

10 – 40 mm

|

10-50mm

|

|

Speed

|

15m/min

|

|

|

Total Electrical Power

|

3kw

|

11kw

|

|

Total Air Pressure

|

6 bar

|

|

|

Total Air Usage

|

160 l/ min

|

180 l/min

|

|

Front Milling

|

-

|

1 x 2.2 kw / 12000 Rpm

1 x 1.5 kw / 12000 Rpm

|

|

Trimming

|

2 x 0.75 kw / 18000 Rpm

|

|

|

Buffing Motor

|

2 x 0.18 kw / 18000 Rpm

|

|

|

Glue Boiler Engine

|

0.18 Kw/ 900 rpm

|

0.18 Kw/850 rpm

|

|

Pvc Step Engine

|

-

|

0.4 kw

|

|

Double pallet system

|

1.1 kw / 900 Rpm

|

2 x 0.75 Kw/1404Rpm

|

|

Machine Length

|

2600 mm

|

3600 mm

|

|

Machine Width

|

800 mm

|

|

|

Machine Height

|

1500 mm

|

|

|

Machine Weight

|

600 kgs

|

1020 kgs

|

| Video | ||