MULTI-PURPOSE SURFACE SANDING MACHINE

MULTI-PURPOSE SURFACE SANDING MACHINE

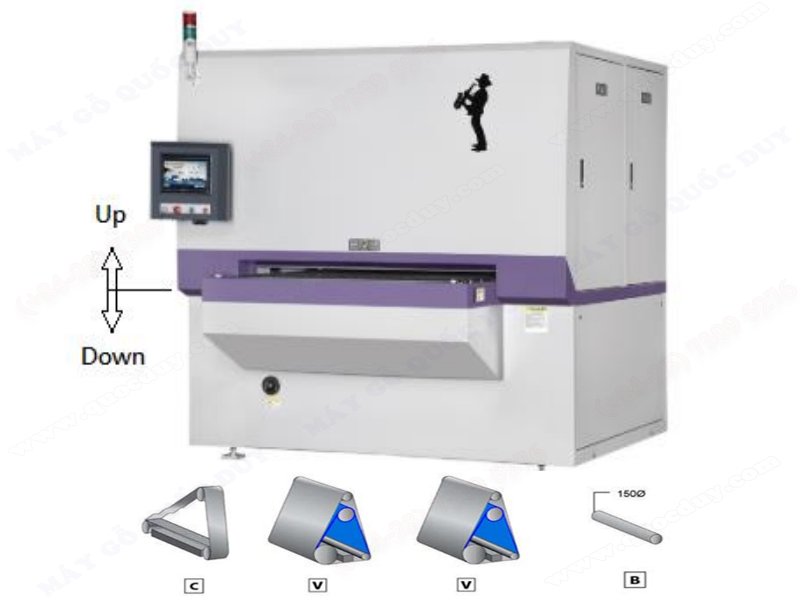

Model : PT-1300CVVB

|

Specifications

|

|

|

- Frame of carbon steel made up of machine.

- With adjustable rubber pressure roller (surface with grooves).

- Sanding paper change on left side.

- Rubber Endless Belt, with automatic device for feed belt tracking

- Feed speed adjustable within 3~19 m/min, and controlled by Inverter.

|

|

|

C - CROSS (with segmented pad function and chevron belt)

|

|

|

Sanding paper size

|

: 5600 x 150mm

|

|

Sanding paper speed

|

: 2-20m/giây

|

|

Motor power

|

: 20HP

|

|

- Electronic segmented PAD

- Pressure beam system provide compensation workpiece tolerance compensation up to ±1 mm.

- Segmented pad will adjust pressure automatically.

- With rubber roller to pressure in-feed and out-feed.

- Use inverter to control sanding paper speed; with two pieces air jet to cleaning cross sanding paper; pressure segment belt system; air system to tight sanding paper; the sanding paper blasting device controlled depending on workpiece.

|

|

|

Longitudinal sanding unit x 2 (with segmented pad function and chevron belt)

|

|

|

- Sanding paper size: L2620mm*W1320mm.

- Sanding paper speed: 2~17m/s.

- Drive motor power: 20HP (15KW).

- Electronic segmented PAD.

- Pressure beam system provide compensation workpiece tolerance compensation up to ±1 mm.

- Segmented pad will adjust pressure automatically.

- With rubber roller to pressure in-feed and out-feed.

- Use inverter to control sanding paper speed; with one piece air jet to cleaning longitudinal sanding paper; air system to tight sanding paper; automatic compensation of differences in the belt length, sanding belt running against feed direction; the sanding paper blasting device controlled depending on workpiece.

|

|

|

Brush device

|

|

|

- Brush roller height could adjustable.

- Brush material: horse hair.

- Diameter: 150mm.

- Drive motor power: 2HP (1.5KW).

|

|

|

Pressure beam of electronic segment PAD

|

|

|

- Controlled by electric rather than air pressure. Therefore, there are no pollution such as jam, un-smooth operation, uneven surface created by cylinder.

|

|

|

Pneumatic system

|

|

|

- Sanding belt with tracking cylinder.

- Air compress cutout valve with lock.

- Air filter F.R.L. (Filtration, Regulation, Lubricant ).

- Self lubricating system for pneumatic components.

|

|

|

Feed conveyor device

|

|

|

Feed conveyor motor power

|

: 5HP

|

|

Lifting device

|

|

|

Lifting motor power:

|

: 0.5HP

|

|

Vacuum device

|

|

|

- Vacuum motor power : 7.5HP (5.5KW).

- For safe transport of workpiece length more than 550mm in direction of feed, including vacuum system.

|

|

|

Controlled system

|

|

|

- Power supply on operate box with lockable switch.

- Profession industrial control operate.

- Touch screen operate with 10.4 inch.

- Screen operate shown by picture and word.

- Operate machine through touch screen by hand input data.

- The left and right edges could setting “plus or minus” pressure data for workpiece processing.

- Feed conveyor speed controlled by Inverter.

- Display position number.

- Starting main motor, and running automatic.

- Overload relay protections on all motors.

- Could monitor in screen, when sanding workpiece.

- Working report (start timer / working timer/ breakdown timer).

- When machine breakdown will shown by picture, alarm bell and flash light, make user to know which part is damage.

|

|